Plastics Cluster - Bioeconomic atlas NCA, Czech clusters and their members

Plastics Cluster introduces its members, Pebal, s. r. o. a Fillamentum Manufacturing Czech s. r. o., which contributed to the Bioeconomic Atlas NCA. The atlas was created thanks to the projects DanuBioValNet (01/17-06/19) and GoDanuBio (07/20-12/22), co-financed by the INTERREG DANUBE programme.

Bioeconomic Atlas NCA introduces clusters, companies and institutions from the NCA membership base dedicated to using renewable biological resources (RBS) for innovative technologies and products.

Plastics Cluster

The Plastics Cluster (PLASTR), founded in 2006, creates a platform for cooperation and development of its members, which are plastics processors. The reasons for establishing the cluster were mainly the traditionally strong position of the plastics industry in the Zlín Region, which, together with the rubber industry, represents the most powerful industrial segment of this region. PLASTR serves to solve the common problems of its 50 members, with the main areas of interest being development and innovation, joint investments, joint purchasing and education. PLASTR's activities are mainly focused on materials research and technological development, and the infrastructure of the Centre for Modelling of Plastic Products and cooperation with the scientific research units of Tomas Bata University in Zlín (UTB) is continuously expanding. Although the transition to renewable biological resources in the plastics industry is very challenging, PLASTR presents two of its members who have already embarked on this path. They are Pebal and Fillamentum.

David Hausner,

director

Sedesatä 5638, 760 01 Zlin

![]()

Pebal s.r.o. was founded in Pilsen in 1995. Over the years, it has grown from an originally commercial organisation to one of the main manufacturers and suppliers of packaging materials in the Czech Republic. At the end of 2018, the company moved to new premises near Dobřany, where a modern production and warehousing area of 50,000 m2 is located.

Pebal's main products include the production of recyclable, biodegradable, printed and laminated multilayer flexible films and packaging with a share of post-consumer and technological recyclates. Pebal's personal approach to customers, emphasis on product quality, and investment in new technologies are the foundations on which it has been building since its founding. Products are manufactured on state-of-the-art machinery, and thanks to the constant innovation of production means, Pebal is able to stay ahead of the competition with an emphasis on sustainability and the environment.

![]()

BIOFOLFLEX is a biodegradable film decomposable in-home compost with OK COMPOST HOME certification by the renowned agency TÜV Austria. Polybutylene succinate (PBS) is compostable in the surrounding environment in open dumps, in home garden composts and in the soil together with other organic waste. It decomposes into biomass, carbon dioxide and water in a short period of time (weeks to months) without the need for special composting equipment. It is made from natural renewable resources such as sugarcane, cane, cassava and maize.

The film has found applications across all segments, including logistics in the food and processing industries. Our customers use this film for packaging magazines, packaging fresh fruits and vegetables, and also for lamination with other compostable materials. Its characteristics include shrinkability, weldability and good optical properties.

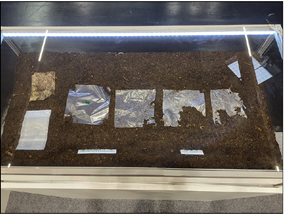

BIOFOLFLEX product demonstration at the Fachpack trade fair in Nuremberg 26.9.-28.9.2022

Fillamentum Manufacturing Czech s. r. o. is a rapidly growing innovative company and a global leader in the production of high-end 3D printing strings (filaments). It has its own research and development department and proudly cooperates with universities and major players in the field of 3D printing.

The company, which is based in the Moravian town of Hulín, currently employs 40 people, making it one of the smaller organisations. Nevertheless, its scope is global. Under the Fillamentum brand, products are distributed to more than 62 countries worldwide. Thanks to this fact, it was also the world's best exporter in the 2018 DHL Unicredit Export Award.

Fillamentum has a wide portfolio of 3D printing materials that will be appreciated by casual printers, but especially by experienced industrial engineers who need special mechanical properties for their applications. High quality is the company's main driver, which is supported by the fact that Fillamentum Manufacturing Czech s.r.o. won the prestigious 3D Printing Industry Awards in the Material Company of the Year category in 2021.

NonOilen

The 3D printing material Fillamentum NonOilen is the result of long-term cooperation with the research team of Prof. Ing. Pavel Alexy, PhD from the Slovak Technical University in Bratislava, who is the author of this unique polymer. It is the only 3D printing filament in the world made from 100% bio-renewable resources. NonOilen® is a blend of polylactic acid and polyhydroxybutyrate (PLA/PHB). Plant starch and natural oil are used in its production.

Printed items are safe for food contact applications and are dishwasher safe. NonOilen filament is multi-recyclable without losing its functional properties. This reduces waste due to, for example, failed printing or if the printed item breaks and can no longer be used. Efficient recycling has been tested several times with minimal loss of functionality.

Once the lifetime of NonOilen is over, when all the properties of the material are lost, the cycle is closed, and the material is 100% returned to nature after decomposition in industrial or even domestic compost, generating biomass, water and carbon dioxide, substances beneficial to the soil. Circulation should end when the nutrients are returned to the soil and plants. This is the part where NonOilen® differs from other well-known materials that are often called "bio" but are not biodegradable. It is not correct that nutrients cannot be returned to the soil. In the case of NonOilen, this process is possible due to the PHB (polyhydroxybutyrate) content, which acts as an initiator of the decomposition process and allows bacteria to "eat" the polymer more quickly. After decomposition, no microplastics remain in the compost to destroy our environment.

Spool of 100% NonOilen degradable filament

NonOilen prints can withstand up to 110°C and are safe for food contact

NonOilen prints can withstand up to 110°C and are safe for food contact