Klastr MECHATRONIKA fosters innovation through the cross-border AM SURF project

Klastr MECHATRONIKA has joined a cross-border project to provide companies with new, more efficient surface treatment options for 3D-printed parts. The project outcomes are continuously shared with industry professionals through workshops and seminars, including regular online meetings of NCA members. Notably, the member institution COMTES FHT will expand its expertise thanks to this project. It will become one of the few Czech research organizations capable of characterizing materials using a confocal microscope.

Klastr MECHATRONIKA, a long-standing National Cluster Association (NCA) member, has established a strong reputation as a reliable project partner and organiser of professional events. The cluster's vision is to create a functional platform for collaboration between businesses, research institutions, schools, and regional authorities to enhance companies' competitiveness and support the region's sustainable development.

As part of its cooperation with COMTES FHT a.s., Klastr MECHATRONIKA has joined the AM SURF project, which also includes partners from Bavaria. This project focuses on optimizing the surface properties of metal parts produced using 3D printing technology, improving the efficiency of their subsequent surface treatment.

This cross-border project, led by COMTES FHT in collaboration with Bavarian partners (OTH Amberg-Weiden and TC Cham), includes the Klastr MECHATRONIKA as a key knowledge and technology transfer partner. Thanks to the active involvement of the cluster and its expertise, the project received support from the Interreg Bavaria – Czech Republic programme and has been successfully implemented since June 2023.

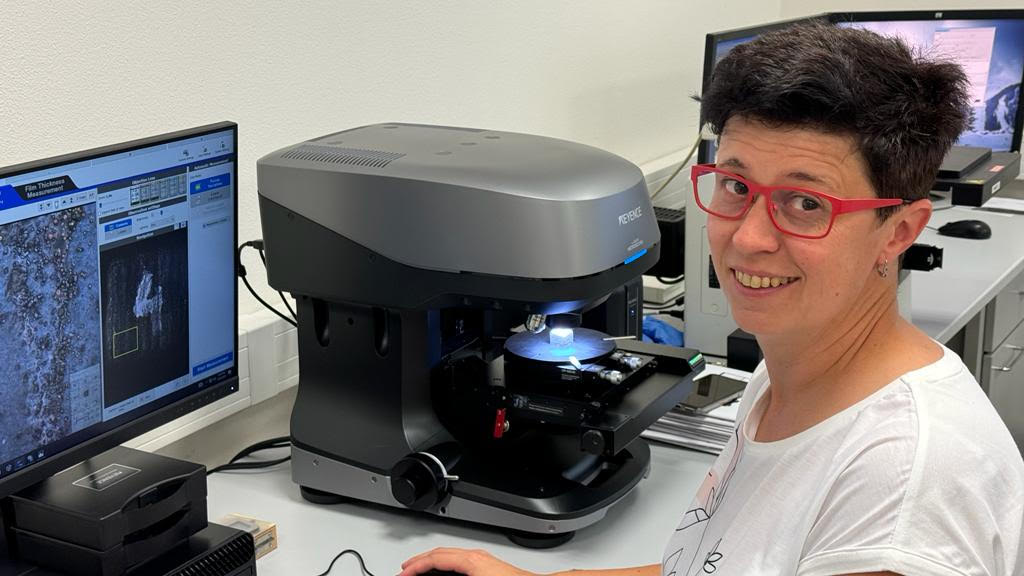

The project provides participating research institutions a unique opportunity to deepen their knowledge of surface quality and post-processing techniques for 3D-printed components. To support these efforts, COMTES FHT acquired a new confocal microscope specifically designed to study surface structure topography. This state-of-the-art equipment enables the research team to expand its portfolio of material analysis methods and develop new technical competencies that will be invaluable for future applications.

Other Klastr MECHATRONIKA members are also actively involved in the project. For instance, LINTECH, one of the leading Czech specialists in laser technologies, has proposed laser processing parameters that the project team is refining to enhance efficiency and minimise the need for extensive post-processing of printed components.

The involvement of the Klastr MECHATRONIKA has provided research institutions with direct access to technology users, ensuring that the project outcomes align with real-world needs. One of the cluster’s most significant contributions is its active role in planning and organising workshops and industry events, allowing the project team to focus on research and optimising results for various industrial sectors while benefiting from strong business engagement.

The AM SURF project is co-funded by the European Union under the Interreg Bavaria - Czech Republic 2021-2027 programme.