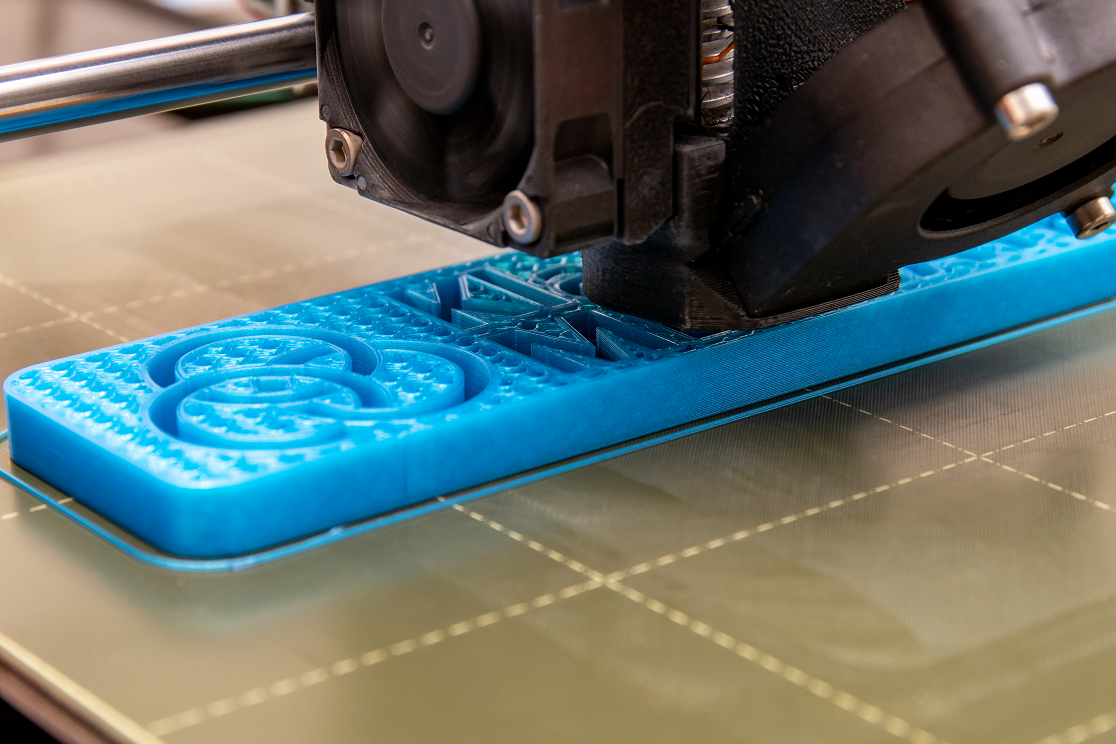

Cluster Mechatronika introduced its activities in additive manufacturing.

Additive manufacturing is becoming an essential part of manufacturing. Although so far, in small batches or specific cases. Cluster Mechatronika is a member of the European TP for additive manufacturing and was one of the first to create a roadmap for additive manufacturing in the Czech Republic.

3D printing can be used almost in all industries. Most common is prototyping, small batch production or special applications. It has a significant position in prosthetics, dental and joint replacements, special splints, etc.

Examples of usage

- Customised parts, mainly prosthetics (implants, splints, exoskeletons), aids (hearing aids, safety helmets, etc.)

- Functional parts (conformal mould cooling, lightweight parts)

- Skillful repairs (repair of casting moulds, turbine blades, shearers) are efficient and extend the service life

- Engine parts - Ferrari in Formula 1 already has parts of its units 3D printed ☺, metal parts printed for gearboxes

- Practical fixtures (maintenance, assembly lines, plastic gauges, employee "improvers")

- Composite parts (plastic+glass fibre/carbon/kevlar) can replace duralloy

- Series production from various alloys (copper, steel...) - precision products with little residual/waste material without the need for demanding to machine

- In the construction industry, printing from concrete (e.g. military fortifications) and similar materials

- Super fashionable things (in Prague, a newly printed bus stop, in Amsterdam, a bridge, in England, they print beehives, in Italy, they print houses from local material, in America, they print custom boats...)

Outlook for the future:

1) Education

- Teach designers to think differently about things (e.g. better moulds for casting sensitive materials with conformal cooling, use of composite materials

- Teach managers to see AM as a possible alternative - not only as a new process for existing materials but perhaps also to look for substitutes in additive technologies where possible

- Schools and the public should be able to integrate 3D printing alongside conventional technologies such as casting, hardening, etc.

- 3D printing allows us to better engage the public in technical education by having them think about the model

2) Industry - innovation, research

- Characterisation of materials and processes, search for alternatives to conventional technologies

- Software development (material standards will be added, software for 3D scanning and reverse engineering, operation of printers, lines, etc. - closely related to automation and digitalisation), in addition, more user-friendly software will be developed for the wider public

- New sets of standards for different sectors

- New materials (gradient, alloys we can't make anymore, composites)

- We will continue to see more development in fields where 3-D printing is already used (toolmaking, fixtures, medicine, medical or sports equipment, and more luxurious products such as cars and glasses...)

- It is expected to develop in areas such as aerospace and automotive since printed products can be lighter yet as strong

- Recycling - we will focus more on how to use "residual" material; we will work with biodegradable materials

- Emphasis will also be on working safely with materials (renovation of production halls - extraction, air filters, suitable storage areas ...)

- Soon, a hybrid form of production will be more developed - i.e. one line/machine that both machines and prints

- We foresee a more significant development of companies that offer printing services 3D printing can reach every industry because it can offer customised solutions and mass production and can work with materials differently than we are used to.

More and in more detail in the roadmap for additive manufacturing, which will be published at the end of October 2022 and will also be on the website www.ctpav.tech

Katerina Podana, Cluster MECHATRONIKA,

|

Created: 24/11/2022 13:57:37

|

|

Created: 24/11/2022 14:02:14

|